| Catalog | Past Items | Order Info | Terms/Conditions | About Us | Inventory Clearance |

This cap belonged to two Confederate soldiers from Tazewell County, Virginia, Allen L. Hash and Lt. George W. Wallace, Company C, 50th Virginia Infantry. On July 2, 1861 Hash and Wallace enlisted from Burke’s Garden (a very small isolated community built in the mouth of an ancient volcano so that it is completely surrounded by mountains). Both were farmers. The 50thVirginia was serving at Carnifax Ferry, in the mountains of Virginia when a battle was fought there in which the Confederates were driven back. It is not known if Hash was captured in arms or was one of the many Confederates in the field hospital with smallpox. Either way he was taken prisoner on September 10, 1861. Eight days later he was at Cross Lanes on his way to an Ohio prison camp. At this time it was discovered that he had enlisted at only fifteen years old. This, however, apparently did not save him and he was never heard from again. Most likely he succumbed to the smallpox under the harsh conditions of the prisoner’s march.

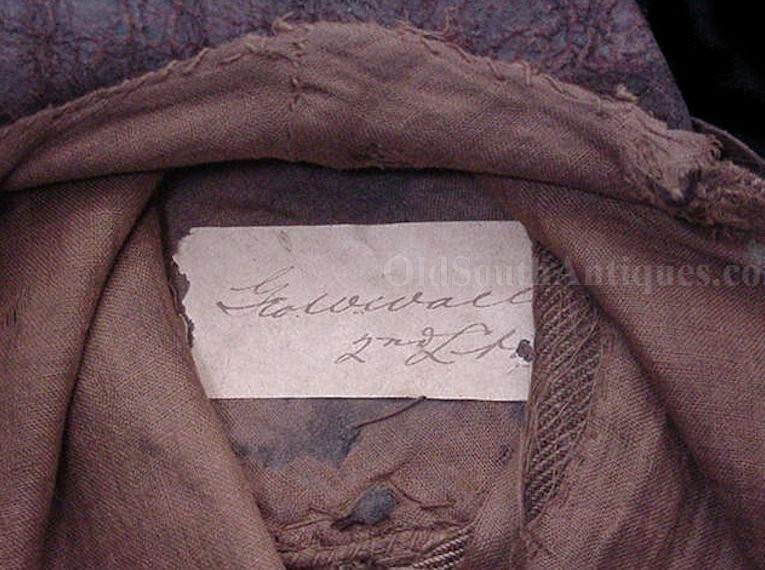

Both men’s names are inside the cap. Hash’s name is sewn into the inner band and Wallace’s name is on a paper label pasted on the inside top. From this we can deduce that Hash first owned the cap and Wallace must have gotten it from him at Carnifax Ferry prior to the formers capture and the latter’s promotion. The paper label must have been applied at some future date when Wallace loaned it to a museum or veteran’s hall collection; certainly he could not have worn it with the paper label in place for any length of time.

Confederate enlisted infantry caps are extremely rare, much more so than Confederate officer’s caps because privates could ill afford to put one aside for sentimental reasons after the War. The cap has had no restoration, yet it is in very good condition, primarily because Private Hash died so early in the War and Lt. George W. Wallace preserved it. The cap has had a complete chemical, fiber and dye analysis which positively dates it to the antebellum period.

The full analysis report is copied below*:

Allen L. Hash Co. C 50th Va. Infantry Cap

Textile Samples Description and Observations

Samples were extracted by Shannon W. Pritchard from an infantry cap for yarn, fiber, and dye analysis: 1 - thread from the "L” in Allen; 2 - Brown fabric sample; 3 - Seam fabric sample; 4 - Sewing thread (see cap image with numbers).

Natural dyes and natural yarn fibers were observed. Yarns and fabrics were hand spun and hand woven into two different fabrics.

(1) Brown embroidery yarn, (2) Brown fabric liner, (3) Brown, inner body seam fabric and (4) Brown Sewing thread from the cap were observed to be: Hand spun threads or yarns in the fabrics. Tabby wove brown fabric (2), twill wove brown (3) were wool or mohair of equal size with cotton warps (see 3 brown fabric close up of brown weft and white warp).

Brown fabric yarns (3), taken from the cap’s seam area in photo, were mohair or fine wool yarn and fiber in the weft with cotton warps and woven in a twill weave. The wool yarns were larger and less twisted than the cotton warps. Both yarns show hand processing due to irregular twists and spin of the two ply cotton warp.

The brown fabric (2) had warps and wefts that are single ply hand spun cotton (see 2 fabric). The irregular quality in the yarns in terms of spin and tension of the weave indicate hand spun yarns and hand woven on a floor loom fabric. Yarns or threads could have been produced by a hand driven or treadle type spinning wheel.

Colors tested: brown liner and brown fabric from inner body seam samples were submitted for dye analysis.

Laboratory Procedures and Results

Samples were taken from the cap by Shannon W. Pritchard. Samples were noted where they were taken on printed color images of the cap, by Mr. Pritchard and submitted with the samples (see cap image with numbers).

The samples were processed to extract the dyes from the yarns using heat, solvent solutions, and varying the Ph. The dyes extracted from the yarns were analyzed using High Pressure Liquid Chromatography (HPLC) and a Photodiode Array (PDA) detector. The HPLC unit runs at 2500 psi. and has 4 solvents and solutions of chemicals to separate mixtures of dyes and identify them individually when they are retained in a 15cm Supelco C18column. Spectrum results generated from the PDA set at 200nm to 400nm had an excellent match with spectrum from dye standards certified by Dr. Helmut Schweppe, a career dye analyst for BASF, Germany. These dye standards are the dye standards used by The Smithsonian Institute in Washington D.C., and the J. Paul Getty Institute in Malibu Beach, Los Angeles, CA. This laboratory uses the only privately owned set of these dye standards in the United States.

Dye Analysis Results

Samples (2) and (3) brown fabrics: Quercus velutina LAM., cortex fructuum (CI N Yellow 10) (Quercitron Bark) - Quercetin (CI 75670) This is the active dye component that yields the brown color. The tree found in North America and Europe is an oak tree that produces the brown dye generating bark. A Spectral Review Report is included for identification of the dye component found in both Samples numbered (2) and (3).

(The above means in laymen's terms, that the there are no synthetic dyes used in the caps construction, assuring that the cap was manufactured before, or during the War between the States)

Yarn and Fiber Analysis

The twist of these yarns is very relaxed, some what irregular, or less twists per inch than the twist of a commercial yarn. Nevertheless, hand carded, hand refined, and hand spun and twisted yarns indicate a lot of care in the materials that went into preparation and processing for this cap. Commercial yarns are frequently a small range of diameter or very close to one size, symmetrical and regular, and form patterns when woven. The samples examined had fiber diameters that were fairly consistent but irregularly twisted from hand processing. The twist on the yarn can indicate heat and moisture while putting tension on the yarn fibers from being dyed. They were originally dipped or passed through a boiling caldron or dye vat, rinsed, and hung to dry. There is a lot of mass or wet wool or cotton pulls on itself and when hot this pulls the fibers straighter. The old worked yarn in these samples showed evidence of such a process.

The micro-photographs show mohair weft and cotton yarn warps and fibers in the fabric sample number (3). Close up examination reveals a scaled wool or mohair weft fibers and cotton fibers used in the warp (see photos number 3).

Sample (2) was found to have brown single ply hand spun brown yarns in both the weft and warp. These yarns had fiber diameter and spin qualities that varied more than one would find in a machine spun yarn. Machine spun yarns are frequently plied or several yarns twisted together for strength and very consistent, as the yarns from this cap’s liner were not. These observations support the notion that the yarns and the weaving were hand done on a cottage level or man power based operations.

Conclusion

The research that included HPLC dye analysis and microscopic analysis of yarns and fibers supports the idea that this is an authentic cap from the Civil War period. *

* Old South Military Antiques now offers an analysis service for Confederate flags, uniforms and caps. Pricing varies so contact me for a price quote on specific items.

* Actual analysis is done by an independent laboratory.

Copyright © 2024 OldSouthAntiques.com All Rights Reserved.

Privacy Policy | Terms of Use

Powered by Web-Cat Copyright © 1996-2024 GrayCat Systems